| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : YUHONG

Model Number : ASTM A335 P9 11CR

Certification : ABS, GL, DNV, NK, PED, AD2000, GOST9941-81, CCS, ISO 9001-2008

Place of Origin : CHINA

MOQ : 100kgs

Payment Terms : L/C, T/T

Delivery Time : 7days

Packaging Details : Ply-wooden Case /Iron Case/ Bundle Package

Standard : ASTM A335

TUBE MATERIAL : P9

FIN TYPE : SERRATED

Application : Heat exchanger,Bolier,Air Cooler

FIN MATERIAL : Carbon Steel, Stainless Steel, Aluminium

FIN THICK : 0.8-3mm

SERRATED FIN TUBE FOR DRYING PLANT ASTM A335 P9 11CR HEAT TRANSFER

Manufacturing Process

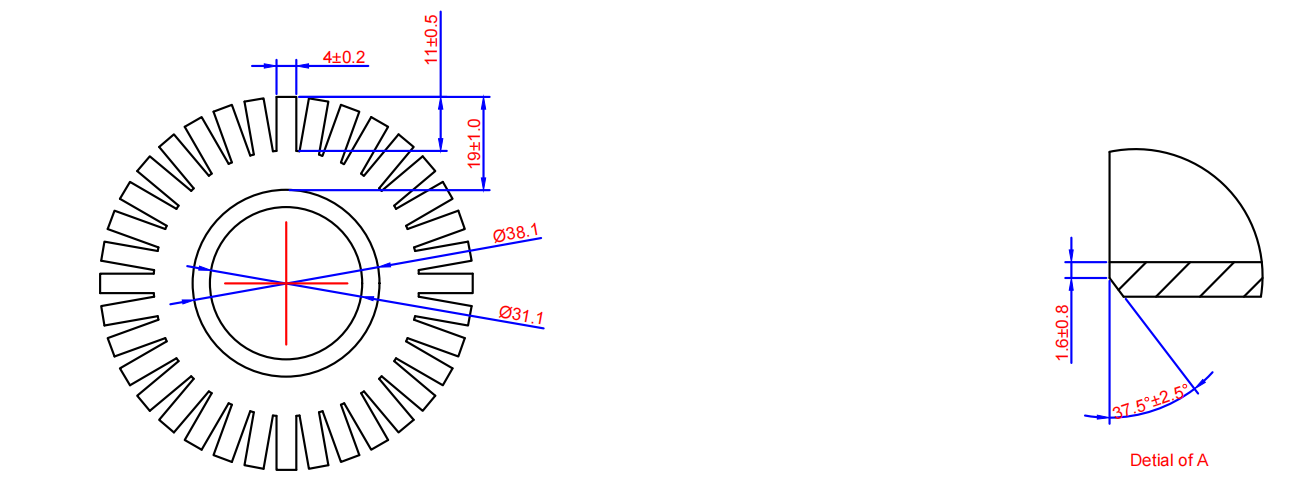

1.Design the serrated fin tube, confirm the detailed parameter with the customers, which mainly includes the pipe length, OD, thickness, fin height, the number of fins within 1 meter and the serrate parameter.

2.Cutting the pipe to fixed length. Customers have different need with the fin tube length, so we need to cut the steel pipe into different length.

3.Split steel coil into steel strap. The height of fins is equal to the width of steel strap, so we need to cut the coil into the strap according to different fins height.

4.Then we need to punch on the strip,and Weld the steel strip on to the steel pipe.

We have one subsidiary, Function is as follow

Detail:

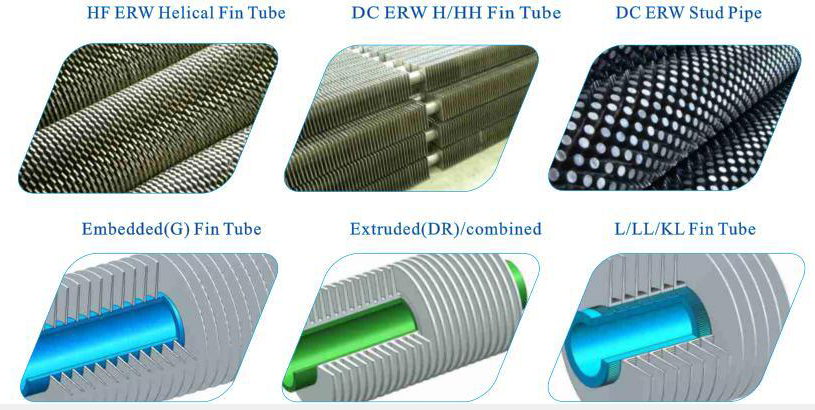

| General extrusion production capacity | General specifications of Extruded Fin Tubes |

| Extrusion Facility: 10 finning machines. Daily capacity up to 3000 meters. Extruded fins type: solid plain and serrated. | Tube OD: 12mm min.~50.8mm(2'') max. Tube Length: 18 meters max. Fin Height: 16.5 mm max. Fin Thickness: appr. 0.4mm/0.5mm/0.6mm Fin Pitch: 1.5mm min. |

Description:

Manufacturing Process

A smooth core tube is inserted into an aluminum sleeve and then the fins are extruded out of the aluminum sleeve.

Fins Type:

The fins are solid plain or serrated into 12,16 or 24 segments or as your design.

Unfinned Section

Both plain ends with appr. 10mm~50mm and gaps (Unfinned Section) in the middle.

Surface Coating

Both bare ends of Bimetallic Finned Tubes shall be Zinc or Aluminum that metallized applied by an electro spray arc system coating.

Accessories

Tube Support Box, Clamp or Spacer Box(Materials: Aluminum, Zinc or Stainless Steel).

Applications:

The common application fileds are:

Specifications:

Extruded Bimetallic Finned Tube is combined with two different materials.

| Items | General Materials | Popular ASTM Materials |

| Core Tube Material | Any metallic materials, as carbon steel, low-alloy steel, stainless steel, brass, copper, cooper-nickel alloys, aluminum bronze, nickel alloys etc. | 1. Carbon Steel: A179, A192,SA210 Gr A1/C,A106 Gr B 2. Stainless Steel: TP304/304L,TP316/TP316L/316Ti, A789 S31803/S2205 etc... 3. Copper:UNS12200/UNS14200/UNS70600, CuNi70/30,CuNi 90/10 4. Titanium: B338 Gr 2 |

| Fins Material | 1. Aluminum Alloy 2. Copper. | 1. Aluminum(Alu.1100,Alu.1060,Alu.6063) 2. Copper. |

| All dimensions are in Inches and specification upon your requests. | |||

| Tube OD | Fin Height | Fin Thickness | Fins per Pitch(Density) |

| 5/8 | 3/8,1/2 | .015/.016/ .020 | 4, 5, 6, 7, 8, 9, 10, 11, 12 |

| 3/4 | 3/8,1/2,5/8 | .015/.016/ .020 | 4, 5, 6, 7, 8, 9, 10, 11, 12 |

| 1 | 3/8,1/2,5/8 | .015/.016/ .020 | 4, 5, 6, 7, 8, 9, 10, 11 |

| 1 1/4 | 3/8,1/2,5/8 | .015/.016/ .020 | 4, 5, 6, 7, 8, 9, 10, |

| 1 1/2 | 3/8,1/2,5/8 | .015/.016/ .020 | 4, 5, 6, 7, 8, 9, 10, 11 |

| 1 3/4 | 3/8,1/2,5/8 | .015/.016/ .020 | 4, 5, 6, 7, 8, 9, 10 |

| 2 | 3/8,1/2,5/8 | .015/.016/ .020 | 4, 5, 6, 7, 8, 9, 10 |

| Please email us for more information. | |||

Competitive Advantage:

|

|

Serrated Fin Tube For Drying Plant Astm A335 P9 11CR Heat Transfer Images |