| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : YUHONG

Model Number : ASTM B462 Hastelloy C276 Spectacle Blind Flange

Certification : ABS, GL, DNV, NK, PED, AD2000, GOST9941-81, CCS, ISO 9001-2015

Place of Origin : China

MOQ : 1PC

Price : Negotiable

Payment Terms : T/T, L/C

Supply Ability : 500 pcs per month

Delivery Time : According to the quantity

Packaging Details : Plywood case

Standard : ASTM B462; ASTM B564

Material : UNS N10276; Hastelloy C276

Type : Spectacle Blind Flange

Size : 1/2'' to 24'' or customized sizes

Pressure class : 150#; 300#; 600#; 900#; 1500#; 2500#

Process : Forged

Overview:

Hastelloy C276 spectacle blind flanges are specialized fittings used in piping systems, particularly in industries dealing with highly corrosive environments, such as chemical processing, oil and gas, and pharmaceuticals. Made from Hastelloy C276, a nickel-molybdenum-chromium alloy, these flanges offer exceptional resistance to pitting, stress corrosion cracking, and oxidizing atmospheres.

The key feature of a spectacle blind is its dual design: one side is a solid plate (blind) and the other is an open ring (spacer). This allows for easy isolation of sections of a pipeline while providing a physical barrier when required. They are typically used in maintenance applications or where temporary isolation is needed.

The durability and strength of Hastelloy C276 make it suitable for high-temperature and high-pressure applications, while its impressive corrosion resistance extends the life of the piping system and reduces downtime. These flanges are usually manufactured to stringent specifications, ensuring precise dimensions and reliable performance.

Installation and maintenance are simplified by their design, promoting safety and efficiency. Compliance with industry standards and specifications, such as ASME and ASTM, ensures that they meet the rigorous demands of industrial applications.

Specification:

| Standard | ASTM B462; ASTM B564 |

| Grade | Hastelloy C276; UNS N10276 |

| Type | Spectacle Blind Flange |

| Size | 1/2''-24'' or customized sizes |

| Class | 150#; 300#; 400#; 600#; 900#; 1500#; 2500# |

| Flange Face | Raise Face; Flat Face; Ring Type Joint |

| Packing | Plywood case/Pallet |

Chemical composition:

| Grade | Ni | Fe | Mn | C | Si | S | Cr | Mo | P | W | Co | V |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| UNS N10276 | balance | 4.0-7.0 | 1.0 max. | 0.01 max. | 0.08 max. | 0.03 max. | 14.5-16.5 | 15.0-17.0 | 0.04 max. | 3.0-4.5 | 2.5 max. | 0.35 max. |

Mechanical Properties:

| Grade | Tensile Strength min, ksi(MPa) | Yield Strength min, ksi(MPa) | Elongation in 2 in. or 50mm, min (%) |

| UNS N10276 | 100(690) | 41(283) | 40 |

Application:

1. Chemical Processing: Ideal for environments with harsh chemicals, such as hydrochloric and sulfuric acids.

2. Oil and Gas Industry: Used in pipelines and vessels where resistant materials are necessary to handle corrosive substances.

3. Pharmaceuticals: Ensures sanitary conditions in processes where corrosion can compromise product integrity.

4. Power Generation: Used in heat exchangers and reactors where high-temperature resistance is required.

5. Marine Applications: Suitable for saltwater environments, helping to prevent corrosion in offshore platforms.

6. Waste Treatment: Effective in handling acidic and corrosive waste solutions.

7. Pulp and Paper Industry: Used in bleaching and chemical recovery processes due to its resistance to chlorine and other corrosive agents.

|

|

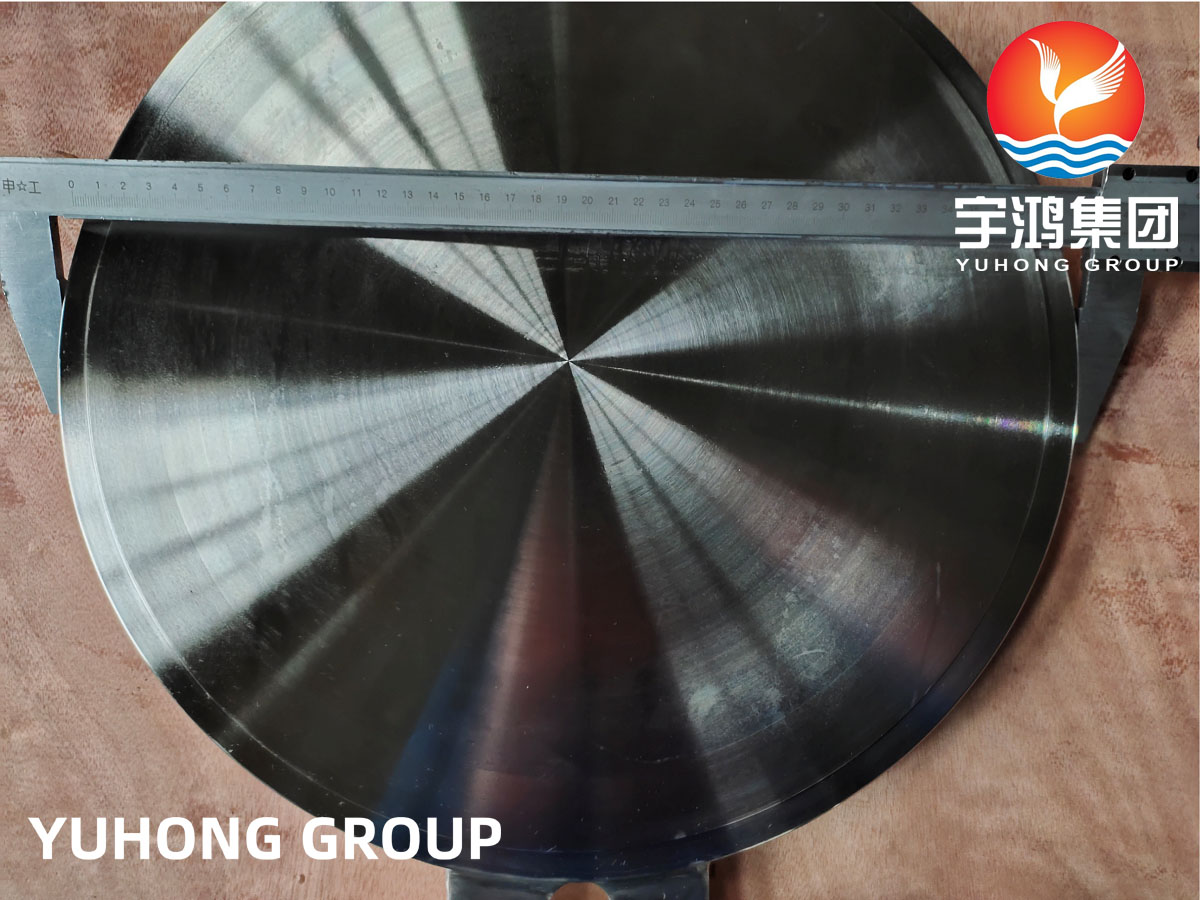

ASTM B462 Hastelloy C276 / UNS N10276 Hastelloy Spectacle Blind Flange Images |